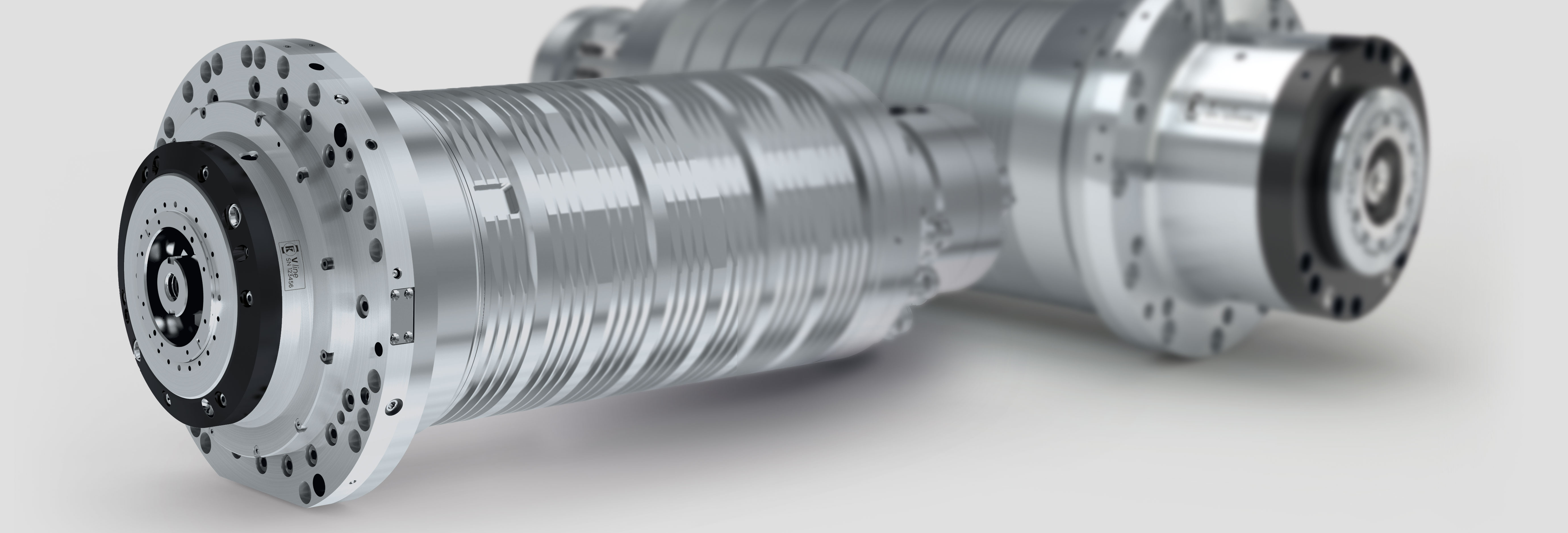

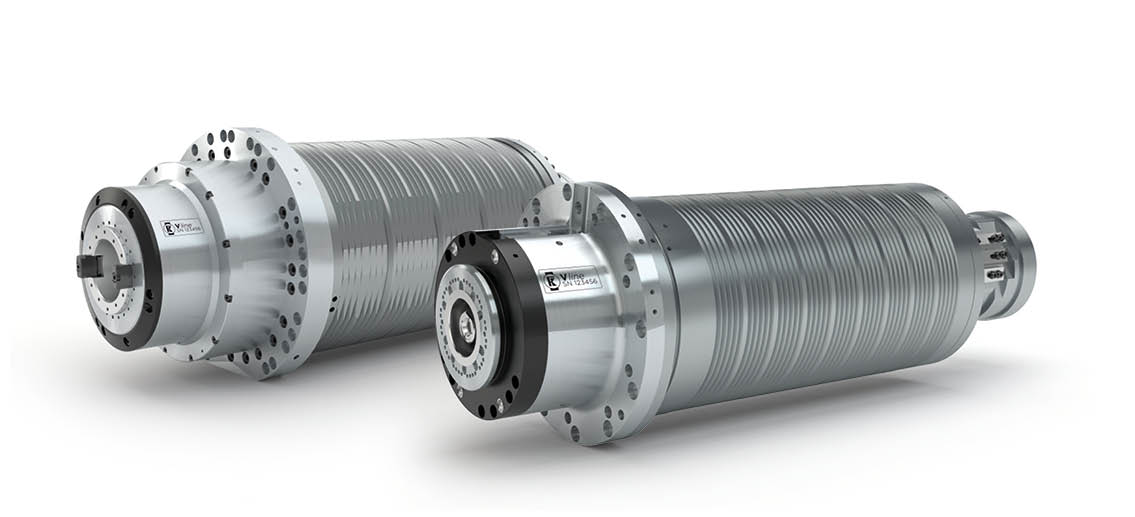

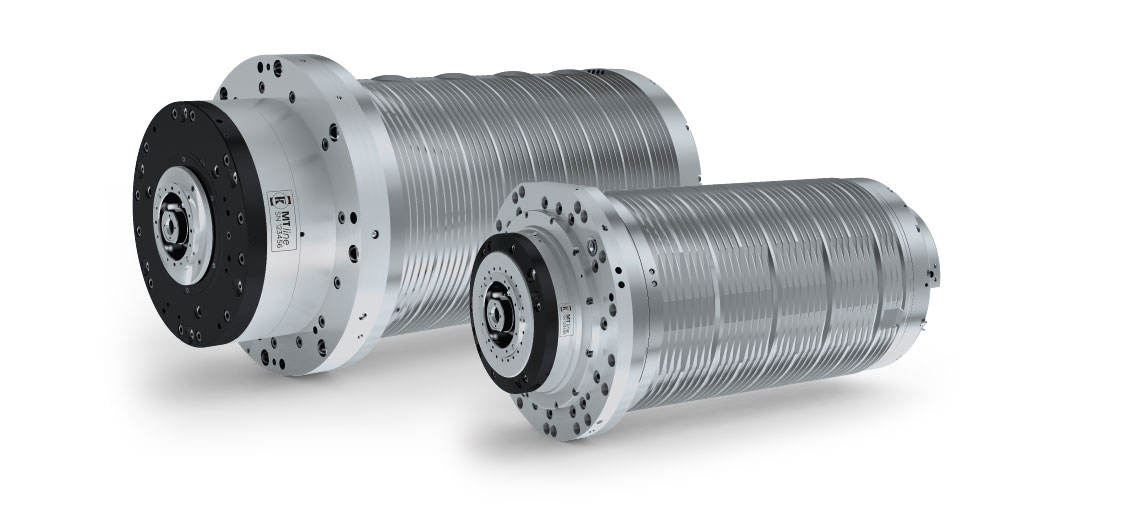

The KESSLER milling spindles have a modular design.

Configure your own milling spindle model by specifying the installation position, motor,

speed, bearing, lubrication and sensory system – the perfect customized solution for your

individual branch and application needs.

KESSLER offers more: As an internationally successful company with extensive and highly specialized expertise, we provide comprehensive advice about the design and manufacture of individual components and project management of complex system solutions. We use the very latest technology and analytical processes to test our components under realistic conditions, so that our products help your business to stay flexible and maintain its competitive edge.

Our in-house development division is supported by extensive calculation and analysis skills

and covers everything from drive technology to the construction of all-in-one systems.

Furthermore, optimized production and assembly lines provide the framework for stable processes

and the superior quality of our milling spindles.

- Vertical machining

- Suitable for tilting operation

- Milling spindle for processing of different materials

- Milling spindle for processing of workpieces with varying geometries

- Use in small and large-scale production

- Short duration until reaching the stable Tool Centre Point (TCP)

- Equipped with shaft clamping for turning operation

- Option to measure the axial shaft displacement

at a glance

- The best matching COOLMOTION® motor for your individual needs:

With very high torque, very high speed or high-compact design - Various bearing lubrication systems available

- Hydraulic, pneumatic or electric release unit available

- High flexibility: KESSLER rotary union for the media: Cooling lubricant,

dry operation, compressed air, minimum cooling lubrication compatibility - Process reliability due to extensive sensory system

- Analog or digital tool clamping status monitoring available on request

- Hydraulic clamping for turning operations available

- High power density due to very compact,

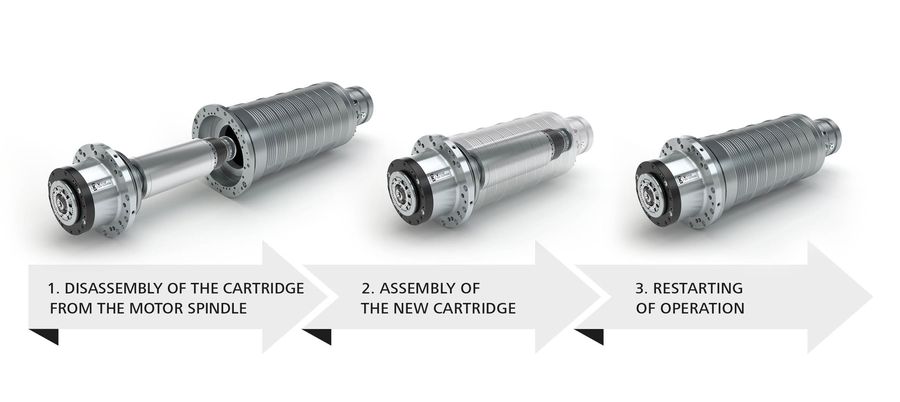

space-saving design and light weight - Reduction of TCO (Total Costs of Ownership) due to the rapid change of the rotor exchange group (KESSLER QCC)

- High availability with the KESSLER tool clamping system

- High flexibility: Various tool interfaces available

- High operational safety with LEDs due to optimal illumination of the tool intervention

- Bearing preload dynamically adaptable to the machining process

- Robust: Designed for high load forces in the machining process

| Model | V100 | V200 | V400 |

| Maximum speed (rpm) | 24,000 | 18,000 | 15,000 |

| Spindle fitting Ø (mm) | 202 | 230 | 270 |

| Tool interface | HSK 63 BBT 40 / SK 40 Capto C6 |

A 100 SK 50 / BBT 50 Capto C8 |

A 100 SK 50 / BBT 50 Capto C8 |

- high flexibility

- optional shaft clamping

- tilting operation optional

- Spindle fitting: Ø 202 mm

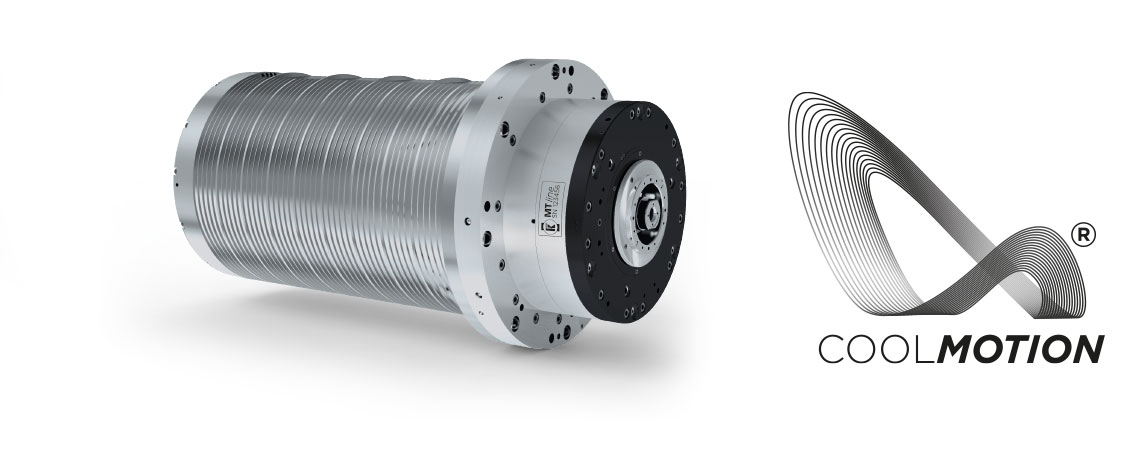

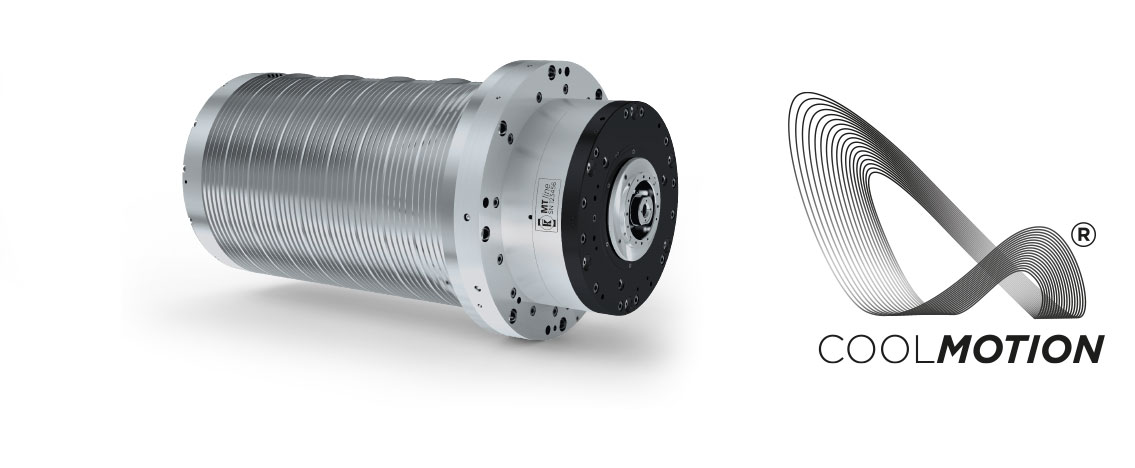

- KESSLER COOLMOTION® motor

- Rotary union: Internal coolant supply with high volume flow

- Cooling: Closed cooling circuit

- Bearing lubrication: Grease / re-greasing / oil-air

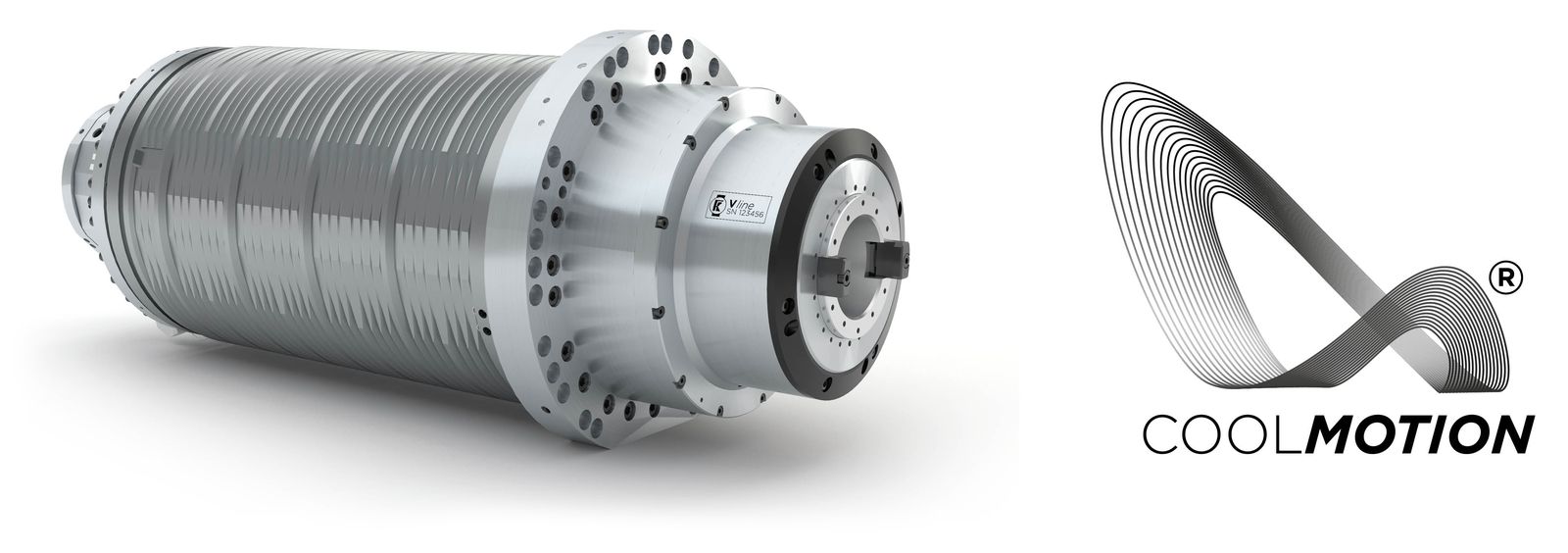

A few of the many KESSLER motors

Select the right COOLMOTION® motor for your needs from our extensive range

| S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Maximum speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

|

| High speed | 24,000 | 70 | 22 | 110 | 35 | 130 | 41 | 190 | 60 |

| High torque | 15,000 | 130 | 30 | 201* | 46 | 217 | 50 | 217 | 67 |

| Bestseller | 20,000 | 87 | 25 | 135* | 40 | 150 | 44 | 203 | 60 |

| Entry-level model | 14,000 | 80 | 15 | 112 | 21 | 129 | 24,5 | 141 | 27 |

Other synchronous and asynchronous motors available on request

* S6 40% / 25% 2min DC

- Spindle diameter: Ø 230 mm

- KESSLER COOLMOTION® motor

- Rotary union: Internal coolant supply with high volume flow

- Cooling: Closed cooling circuit

- Bearing lubrication: Grease / re-greasing / oil-air

A few of the many KESSLER motors

Select the right COOLMOTION® motor for your needs from our extensive range

| S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Maximum speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

|

High speed |

18,000 | 185 | 57 | 205 | 57 | 235 | 57 | 260 | 57 |

| High torque | 12,000 | 235 | 54 | 265 | 54 | 305 | 54 | 335 | 54 |

| Entry-level model | 15,000 | 185 | 57 | 205 | 57 | 235 | 57 | 260 | 57 |

Other synchronous and asynchronous motors available on request

- Spindle fitting: Ø 270 mm

- KESSLER COOLMOTION® motor

- Rotary union: Internal coolant supply with high volume flow

- Cooling: Closed cooling circuit

- Bearing lubrication: Grease / re-greasing / oil-air

A few of the many KESSLER motors

Select the right COOLMOTION® motor for your needs from our extensive range

| S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Maximum speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

|

| High speed | 15,000 | 300 | 48 | 445 | 70 | 535 | 84 | 640 | 100 |

| High torque | 10,000 | 365 | 46 | 510 | 64 | 630 | 80 | 750 | 95 |

| Entry-level model | 15,000 | 220 | 35 | 305 | 48 | 350 | 56 | 405 | 65 |

Other synchronous and asynchronous motors available on request

- Choose the best matching KESSLER COOLMOTION® motor for your needs

- KESSLER rotary union

- Cooling lubricant

- Dry operation

- Compressed air

- Minimum cooling lubrication capability - Sensor monitoring system

- Face end contact monitoring

- Vibration sensor

- Analog sensor

- Eddy current sensor

- Clamping status monitoring

- Clamping monitoring

- Leakage monitoring

- Temperature sensor PT100

- Hydraulic clamping

- Bearing preload: Variable

- Bearing lubrication: Grease / re-greasing / oil-air

- Closed cooling jacket

- Clamping spring package is designed for 5 million tool changes

- Standard cable outlet, connector optional

- Holding-function for collet chuck: Variable

- 2-channel rotary union

- Oil-air lubrication unit

- Re-greasing unit

- Direct lubrication: on demand

- achieves a very high torque density

- achieves very short acceleration times

- performance-enhanced motors for a compact design

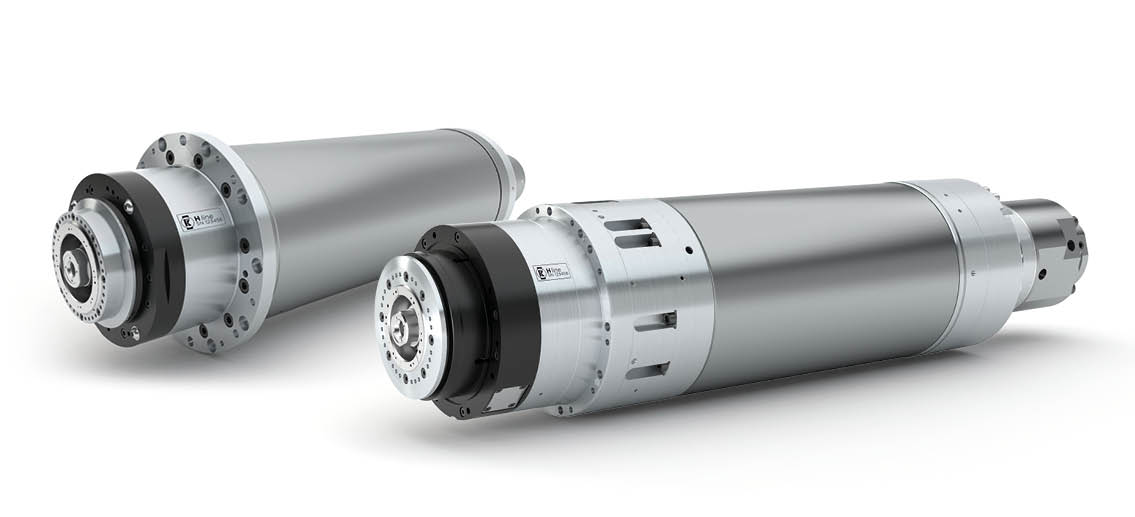

- 5-axis machining

- Very short construction thanks to release unit and rotary union integrated in the shaft

- Can be used in tilting heads

- Processing of different materials

- Machining of workpieces with varying geometries

- Use in small and large-scale production

- Short duration until reaching the stable Tool Centre Point (TCP)

- As an option, can be supplied with clamps for turning operations

- Option to measure the axial shaft displacement

at a glance

- The most suitable COOLMOTION® motor for your individual needs:

With very high torque, very high speed or high-compact design - Various bearing lubrication systems available

- Hydraulic release unit

- High flexibility: KESSLER rotary union for the media: lubricant,

dry operation, compressed air, MQL capability - Process reliability due to extensive sensory system

- Process reliability due to extensive sensory system

- Analogue tool clamping status monitoring

- Hydraulic clamping for turning operations available

- High power density due to very compact,

space saving design and light weight - Reduction of TCO (Total Costs of Ownership) due to the rapid change of the rotor exchange group (KESSLER QCC)

- HSK and Capto tool interfaces

- High degree of operational safety thanks to LEDs due to optimal illumination of the tool intervention

- Robust: Designed for high load forces in the machining process

| Model | MT80 | MT100S | MT100L | MT100H | MT400 | MT500 | MT600 |

| Maximum speed (rpm) to | 24,000 | 20,000 | 20,000 | 16,000 | 15,000 | 10,000 | 8,000 |

| Torque S6 / 40% (Nm) to | 95 | 120 | 210 | 235 | 560 | 850 | 1,250 |

| Spindle fitting Ø (mm) | 170 | 202 | 202 | 202 | 270 | 325 | 395 |

| Length overall (mm) | 475 | 385 | 475 | 530 | 628 | TBD | TBD |

| Tool interface | HSK 63 Capto C6 |

HSK 100 Capto C8 |

HSK 125 Capto C10 |

||||

- very short construction

- very short vector length

- high effective torque at the tool cutting edge

- Quick Connect Cartridge (QCC)* reduced machine downtimes for servicing

- optional shaft clamping

*Not with MT80 and MT600

- Spindle fitting: Ø 170 mm

- KESSLER COOLMOTION® motor

- Cooling: Open cooling housing

- Bearing lubrication: Oil-air / re-greasing

Choose the most suitable COOLMOTION® motor from the list of preferred motors

| Model | S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Max. Speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

||

| MT80-S24 | 24,000 | 26 | 20 | 34 | 26 | 38 | 29 | 45 | 34 | High speed |

| MT80-S20 | 20,000 | 80 | 45 | 95 | 45 | 110 | 45 | 145 | 45 | High torque |

Available on request

Not available with Quick Connect Cartridge (QCC)

- Spindle fitting: Ø 202 mm

- KESSLER COOLMOTION® motor

- Cooling: Open cooling housing

- Bearing lubrication: Oil-air / re-greasing

Choose the most suitable COOLMOTION® motor from the list of preferred motors

| Model | S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Max. Speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

||

|

MT100S-S20 |

20,000 | 85 | 20 | 100 | 20 | 115 | 20 | 170 | 20 | High speed |

|

MT100S-S12 |

12,500 | 100 | 36 | 120 | 40 | 130 | 43 | 180 | 48 | High torque |

|

MT100L-S20 |

20,000 | 130 | 45 | 160 | 45 | 180 | 45 | 200 | 45 | High speed |

|

MT100L-S12 |

12,500 | 175 | 54 | 210 | 54 | 235 | 54 | 280 | 54 | High torque |

|

MT100H-S16 |

16,000 | 150 | 40 | 180 | 40 | 200 | 40 | 250 | 40 | High speed |

|

MT100H-S12 |

12,500 | 200 | 54 | 235 | 54 | 265 | 54 | 315 | 54 | High torque |

Available on request

- Spindle fitting: Ø 270 mm

- KESSLER COOLMOTION® motor

- Cooling: Open cooling housing

- Bearing lubrication: Oil-air / re-greasing

Choose the most suitable COOLMOTION® motor from the list of preferred motors

| Model | S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Max. Speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

||

|

MT400-S15 |

15,000 | 315 | 87 | 365 | 87 | 375 | 87 | 390 | 87 | High speed* |

|

MT400-S12 |

12,000 | 500 | 75 | 635 | 75 | 670 | 75 | 700 | 75 | High torque* |

*Available on request

- Spindle fitting: Ø 325 mm

- KESSLER COOLMOTION® motor

- Cooling: Open cooling housing

- Bearing lubrication: Oil-air

Choose the most suitable COOLMOTION® motor from the list of preferred motors

| Model | S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Max. Speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

||

|

MT500-S6 |

6,000 | 800 | 67 | 930 | 67 | 1,000 | 67 | 1,100 | 67 | |

- Spindle fitting: Ø 395 mm

- KESSLER COOLMOTION® motor

- Cooling: Open cooling housing

- Bearing lubrication: Oil-air

Choose the most suitable COOLMOTION® motor from the list of preferred motors

| Model | S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Max. Speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

||

|

MT600-S5* |

5,000 | 1,200 | 75 | 1,350 | 75 | 1,500 | 75 | 1,600 | 75 | |

*Available on request

Not available with Quick Connect Cartridge (QCC)

- Choose the most suitable KESSLER COOLMOTION® motor

- Sensor monitoring system

- Vibration sensor

- Eddy current sensor detects axial shaft displacement

- Clamping status monitoring

- Clamping monitoring

- Temperature sensor PT100 - Hydraulic clamping

- Bearing preload

variable

- Closed cooling jacket

- Clamping spring package is designed for 3 million tool changes

- Oil-air lubrication unit

- Re-greasing unit on demand

- Direct lubrication: on demand

- Horizontal machining

- Typical applications: Automotive industry, process machines

- Milling spindle for machining of similar work pieces, with similar working cycles with a high work frequency

- Milling, drilling, thread cutting, grinding, boring of

aluminum, cast iron and steel - Internal monitoring of milling spindles (condition monitoring)

- Tool clamping system designed for a maximum amount of tool changes

- High speed: Up to 25,000 rpm

- High torque: More than 400 Nm

at a glance

- The best matching COOLMOTION® motor for your individual needs: With very high torque, very high speed or high-compact design

- Various bearing lubrication systems available

- Hydraulic or electric release unit available

- High flexibility: KESSLER rotary union for the medias: lubrication, dry operation, compressed air, minimum cooling lubrication compatibility

- Process reliability due to extensive monitoring system

- Spindle fitting diameter and position: The spindle fitting diameter can be configured accordingly to meet your specific requirements

- High productivity with the KESSLER tool clamping system – Clamping spring package is designed for 5 million tool changes

- High productivity due to short acceleration and braking times

- Milling spindle with end face contact monitoring

- Removable assembling flange

- Variable interface: Full contact plane surface or segmented plane surface

- Various spindle heads available

– Individual shapes can be defined as required - High operational safety with LEDs due to optimal illumination of the tool intervention

- 2x or 4x bearings available

| Model | H80 | H100 | H200 |

| Speed (rpm) |

25,000 |

20,000 | 15,000 / 16,000 |

| Spindle fitting Ø (mm) | 170 | 200 | 240 |

| Tool interface | HSK 63 | HSK 63 | HSK 100 / 63 |

- very short acceleration times

- high power

- low rotor torque of inertia

- Spindle fitting: Ø 170 mm

- KESSLER COOLMOTION®motor

- KESSLER tool clamping system: Clamping spring package

is designed for 5 million tool changes - Rotary union: Inner coolant supply

with large volume flow - Cooling: Closed cooling circuit

- Bearing lubrication: Grease / re-greasing / oil-air

A few of the many KESSLER motors

Select the best matching COOLMOTION®-motor for your needs from our extensive range

| S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Maximum speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

|

| High speed | 25,000 | 80 | 33 | 100 | 33 | 105 | 33 | 115 | 33 |

| High torque | 20,000 | 95 | 33 | 110 | 33 | 125 | 33 | 140 | 33 |

| Entry-level model | 24,000 | 40 | 16 | 60 | 24 | 75 | 30 | 95 | 38 |

Other synchronous motors available on request

- Spindle fitting: Ø 200 mm

- KESSLER COOLMOTION®motor

- KESSLER tool clamping system: Clamping spring package

is designed for 5 million tool changes - Rotary union: Internal coolant supply with high volume flow

- Cooling: Closed cooling circuit

- Bearing lubrication: Grease / re-greasing / oil-air

A few of the many KESSLER motors

Select the best matching COOLMOTION®-motor for your needs from our extensive range

| S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Max. Speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

|

| High speed | 20,000 | 120 | 36 | 140 | 36 | 150 | 36 | 165 | 36 |

| High torque | 15,000 | 170 | 32 | 210 | 32 | 235 | 32 | 270 | 32 |

| Entry-level model | 20,000 | 60 | 19 | 90 | 28 | 112 | 35 | 172 | 54 |

Other synchronous and asynchronous motors available on request

- Spindle fitting: Ø 240 mm

- KESSLER COOLMOTION®motor

- KESSLER tool clamping system: Clamping spring package

is designed for 5 million tool changes - Rotary union: Internal coolant supply with high volume flow

- Cooling: Closed cooling circuit

- Bearing lubrication: Grease / re-greasing / oil-air

A few of the many KESSLER motors

Select the best matching COOLMOTION®-motor for your needs from our extensive range

| S1 | S6 / 40% | S6 / 25% | S6 max. | ||||||

| Max. Speed (rpm) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

Torque (Nm) |

Power (kW) |

|

| High speed | 16,000 | 160 | 63 | 180 | 63 | 215 | 63 | 231 | 63 |

| High torque | 10,000 | 350 | 55 | 390 | 55 | 460 | 55 | 500 | 55 |

| Entry-level model | 14,000 | 200 | 42 | 300 | 62 | 300 | 62 | 300 | 62 |

Other synchronous and asynchronous motors available on request

- Spindle heads: variable

- Bearing: 2x or 4x bearings available

- Choose the best matching KESSLER COOLMOTION® motor for your needs

- KESSLER rotary union

- Cooling lubricant

- Dry operation

- Compressed air

- Minimum cooling lubrication capability - Spindle fitting Ø (position A and B side): variable

- Sensor monitoring system

- Face end contact monitoring

- Vibration sensor

- Clamping status monitoring

- Leakage monitoring

- Temperature sensor PT100

- Segmented plane surface

- Bearing preload: variable

- Assembling flange removable

- Bearing lubrication: Grease / re-greasing / oil-air

- Standard cable outlet, connector optional

- Holding-function for collet chuck: variable

- 2-channel rotary union

- Oil-air lubrication unit

- Re-greasing unit

- Direct lubrication: on demand

- achieves a very high torque density

- achieves very short acceleration times

- performance-enhanced motors enable a compact design

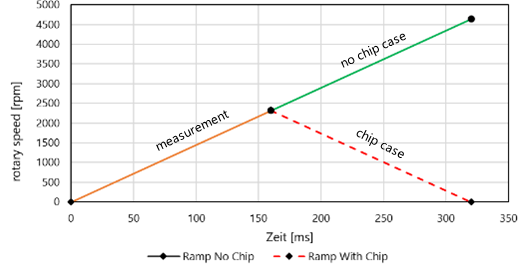

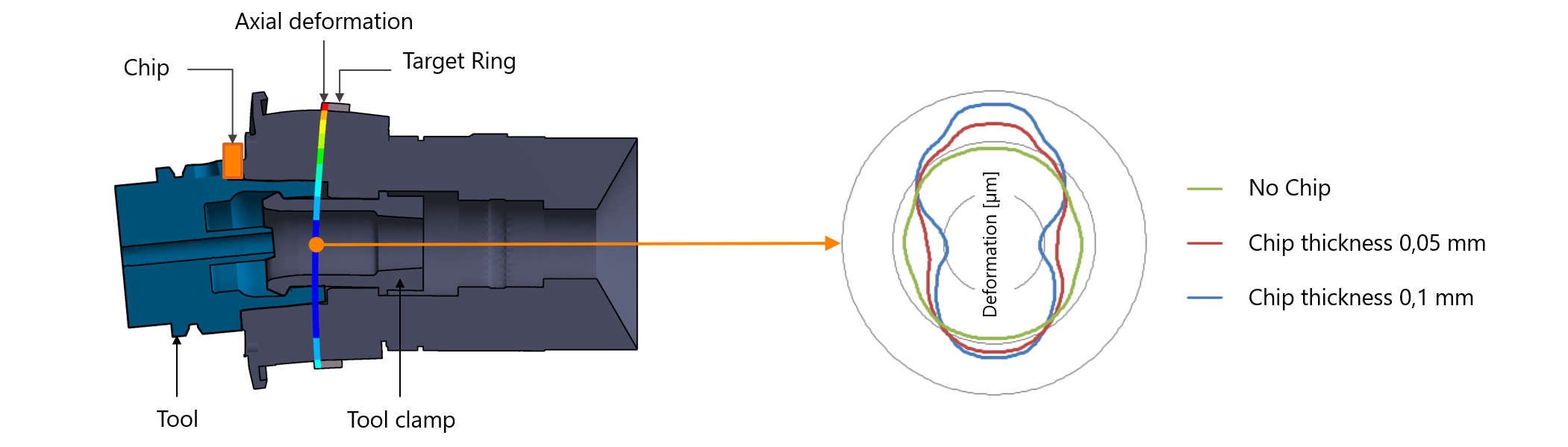

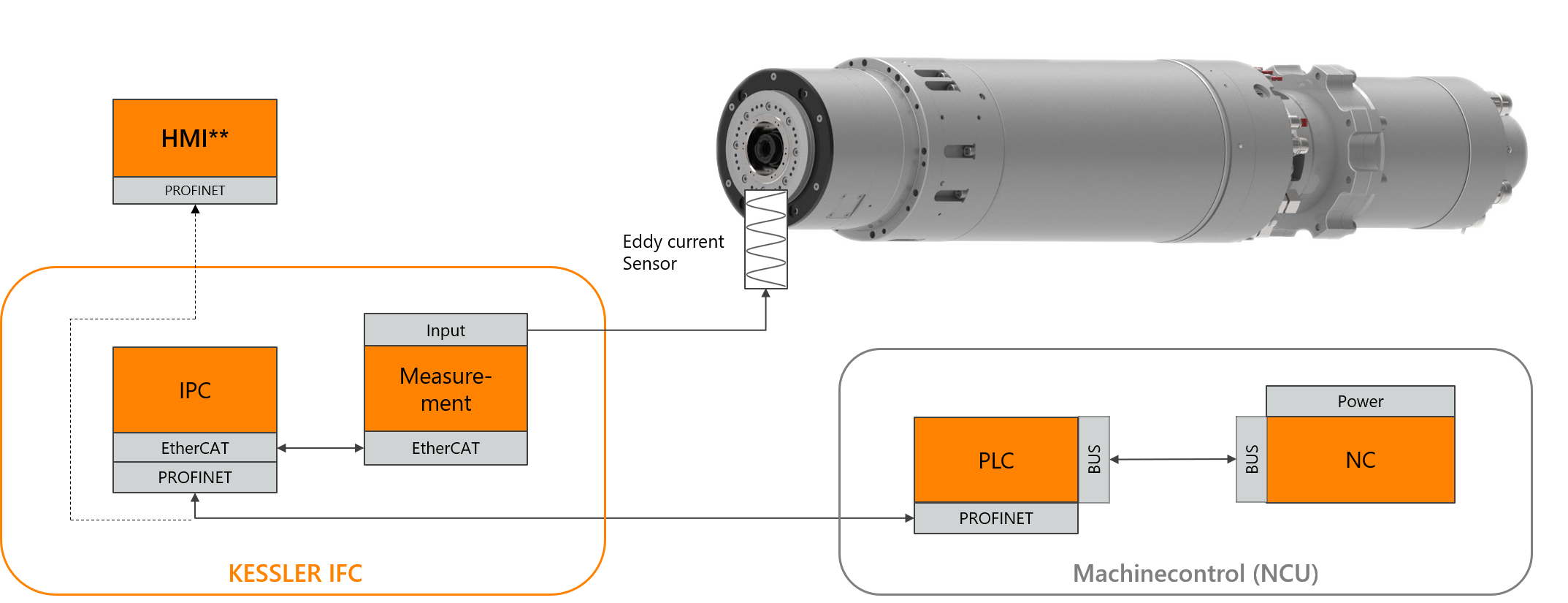

The InterFace Control System (IFC) is a face detection system for detecting a tilted position of the tool in the tool interface caused by a foreign object such as a chip caught between the tool face and spindle. A sensor installed in the bearing cover of the spindle measures the deformation or deformation of the toolholder on a ring gauge. The measurement takes place either during acceleration of the spindle or at constant speed. The communication between the industrial PC and the controller takes place via PROFINET. An application especially for machining processes where a particularly high accuracy of tool clamping is required.

o Process safety: High reliability through > 99 % detection probability

o Sensitivity: Chips > 40 µm directly detectable. Small chips, between 20 µm and 40 µm visible with teaching

o 100% detection range: Chip detection over the entire circumference of the flat surface

o High robustness and long service life due to non-contact measurement without the need for rotating parts or rotary transmitters

o Main time neutral: Due to the measuring possibility during the acceleration phase, no interruption of work necessary; alternatively also possible at constant speed

o Speed stability: suitable for speed ranges up to 30,000 rpm

o Evaluation electronics outside the spindle: low integration effort, installation in short spindles possible

o Length growth sensor included, without additional sensor

o Fast switch-off option when chips are detected due to the shortest measuring time within only three spindle revolutions (see Kessler Motor Spindle H80 < 150 ms)

o Can be integrated into the H80, H200, V100, MT80 and MT100 spindles and many more on request

o Maintenance/sensor exchange possible with installed spindle

Tools act with a force on the flat surface and on the cone surface and create an individual Deformation. Deformation can be detected by an eddy current sensor on a rotating measuring ring.

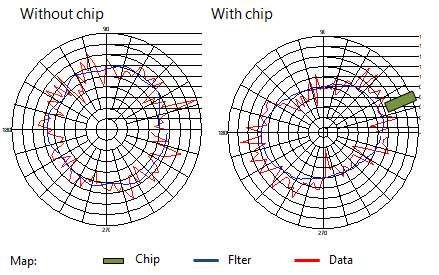

Chip between toolholder and spindle shaft produces an uneven deformation

o Chip size LxWxH:

- >7×1×0,04 mm (steel chip, without reference measuring)

- <7×1×0,04 bis >7×1×0,02 mm (steel chip, with needed reference measuring)

o PROFINET connection for PLC communication

o Optional Connection to screen Input device (HMI)

o Chips > 40 µm directly visible

o Small chips with a size between 40 µm and 20 µm and left-hand rotating tools require teaching

o Achievable accuracy depends on the spindle and the sensor position

- HSK 63 è 20-30 µm

- HSK 100 è 30 µm

o PROFINET

o GSD file describes interface

o Industrial standard protocol

o Customer can choose between different measurement Options

- Ramp, constant, with reference, without reference

o Shaft displacement

o Customer receives status, error message

o Future measurements