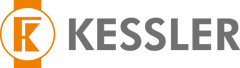

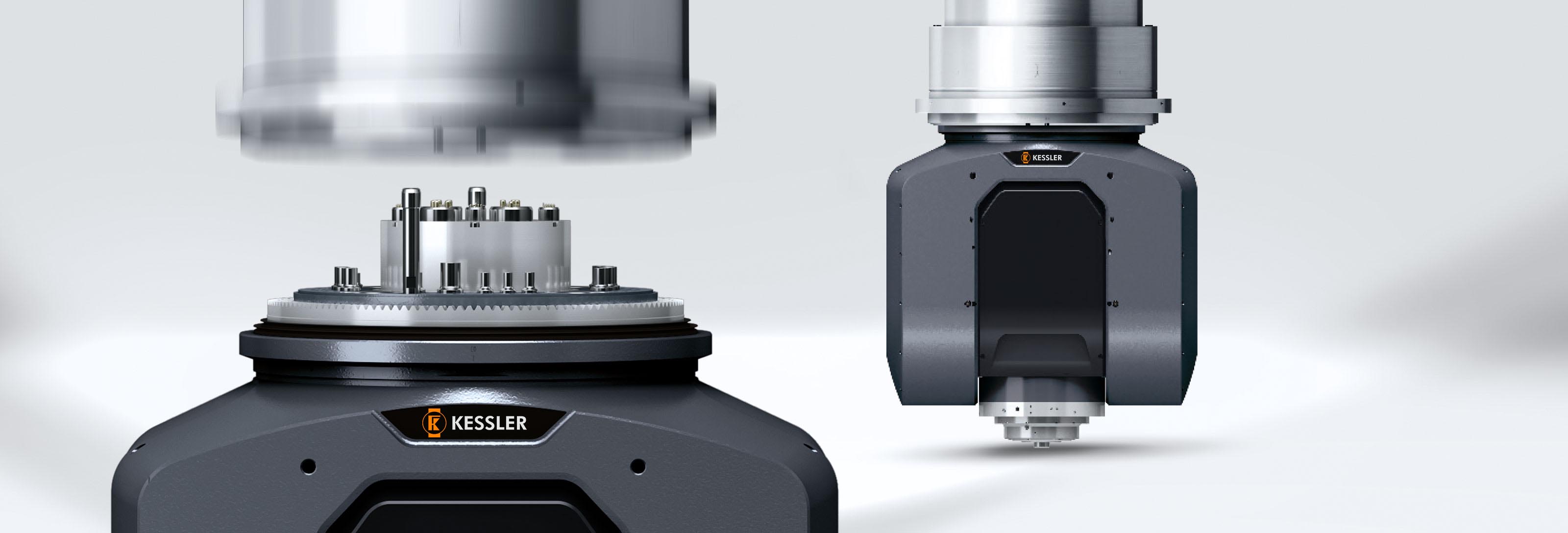

Two-axis heads with KESSLER spindles and motors

Intelligent systems: KESSLER heads think ahead – Head line

Applications with high requirements need a reliable partner. KESSLER 2-axis heads provide a compact and rigid design with high flexibility for numerous applications within your machine.

KESSLER’s latest torque motor generation achieves a high dynamic which is required especially when milling very intricate and narrow workpiece contours.

High positioning accuracy, high clamping force and a large tilting angle ensure that precise results are achieved in 5-axis machining.

KESSLER also offers compatible spindles for use with our 2-axis heads, to fulfill your machining needs.

The right head for every position:

KESSLER 2-axis heads available from MINI to MEDIUM + Quick Axis Change (QAC)

- Individual configurability due to modular design

- Reliable skilled partner - for 2-axis heads, spindles and motors

- High clamping torque in the C-axis

- High maximum torque

- High accuracy Secondary cooling in the C-axis reduces the heat input in the headstock to a minimum

- Very maintenance friendly Wear parts can be easily replaced on site

- Spindles are optionally available with shaft clamping for turning operations

- Robust design with monolithic fork

- Precise machining results - due to high positioning accuracy

- High flexibility - and suitability for numerous applications

- High productivity due to high tilting speed

- High clamping torque in the A-axis

- High dynamics due to the newest generation of powerful COOLMOTION® motors

- High degree of operational safety thanks to LEDs due to optimal illumination of the tool intervention

- High productivity thanks to high-torque motor spindles

- With new spindle-generation MT + P LINE

- With Quick Connect Cartridge (QCC)*

*does not apply to MT80 and MT600