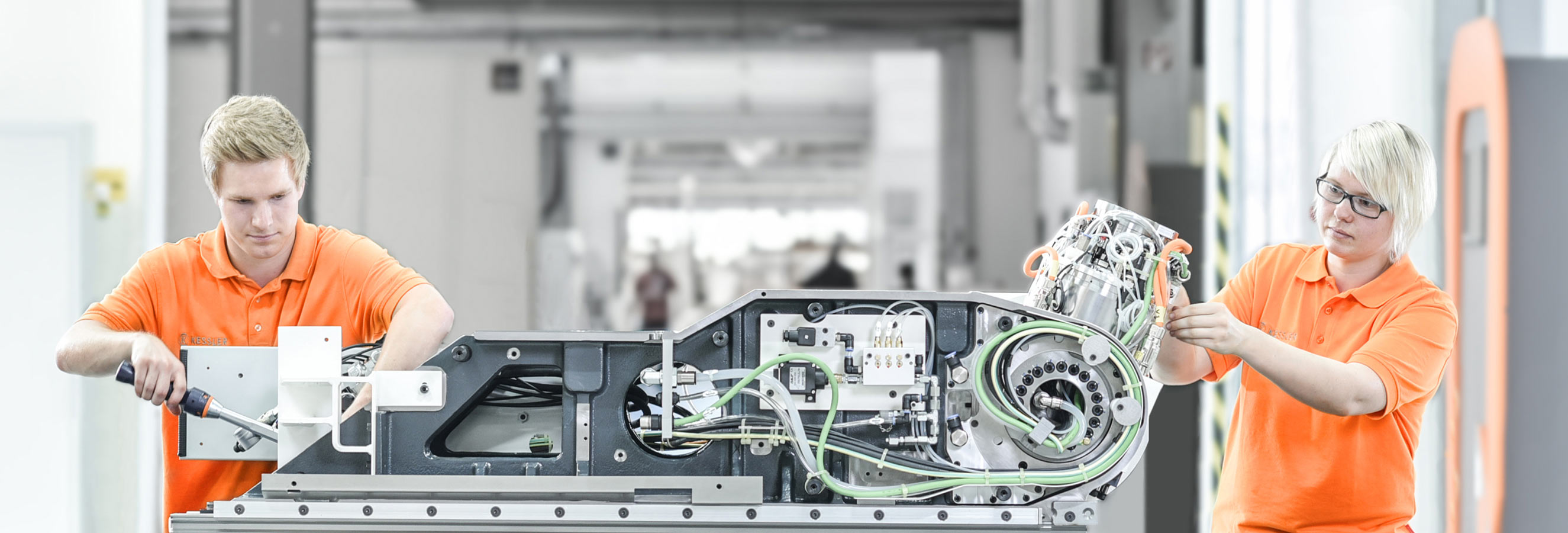

Spindle service, spindle repair, one-stop service solutions

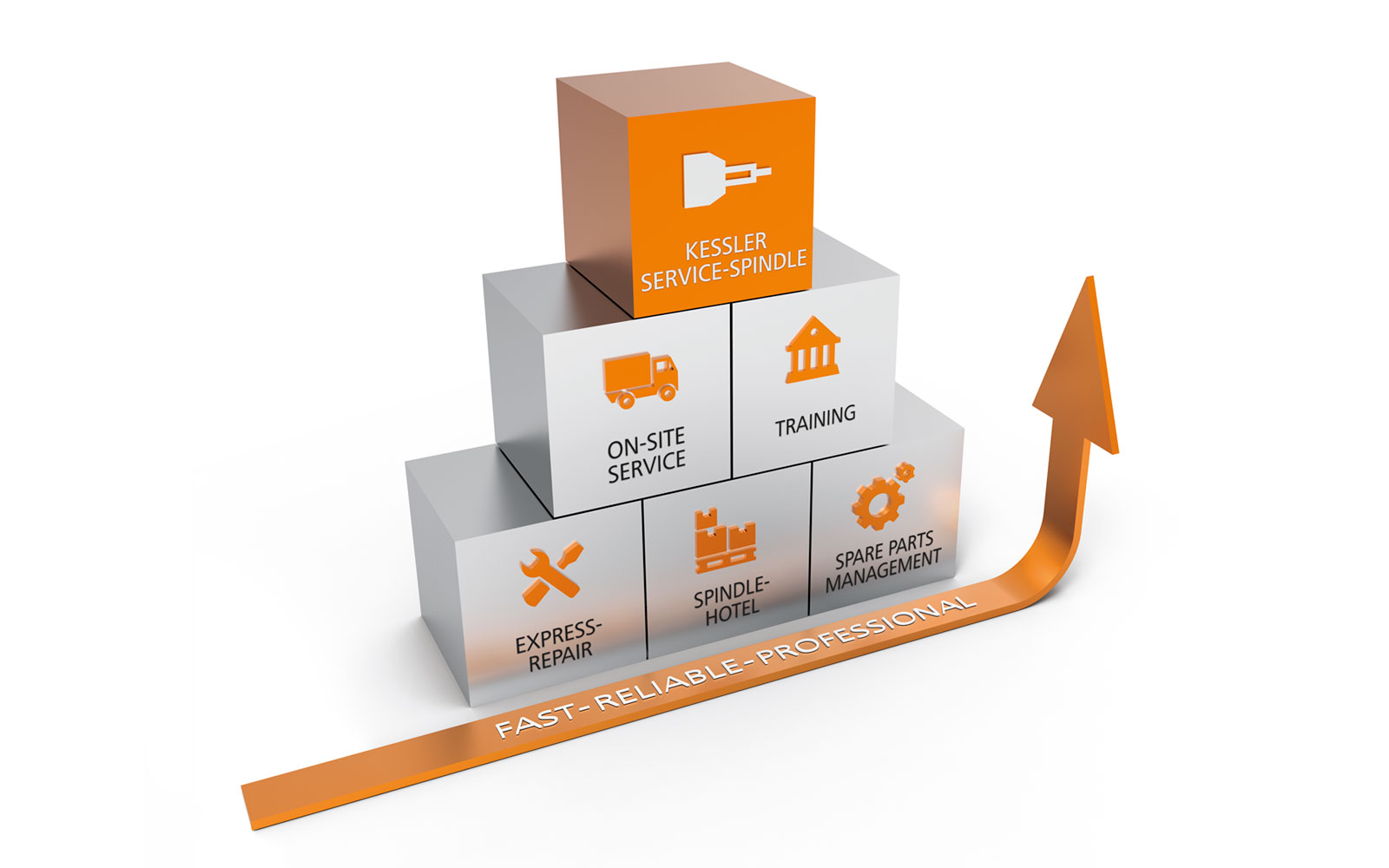

Service is a matter of trust! As a specialist for spindle service and a partner to the machine tool manufacturing industry, KESSLER provides its customers with a wide range of integrated services.

By using the same equipment worldwide – from the workbench to the tools, KESSLER ensures consistent quality at the highest standard. Put your trust in the expertise and experience of more than 90 years of forward-looking development work.

Rely on the service team at KESSLER for full support with its detailed process and fault analysis, repair service, spindle replacement assistance or whenever you need spare parts. Whatever your needs, you will always profit from our fast reaction times, optimum price-performance ratio and maximum quality

standards for products and services.

![]()

Express-Repair

- Express Repair in 5 – 10 Days

- Dependable repairs at the highest quality level

- Capable on-site support

- Expertise directly from the manufacturer

![]()

Spindle-Hotel

- Professional storage according

to optimal conditions - Delivery on demand

![]()

Spare Parts Management

- Original spare parts directly from the manufacturer

- Customer-orientated service solutions

- Longer spindle service life due to original replacement parts

… at optimum fine-tuning of our products

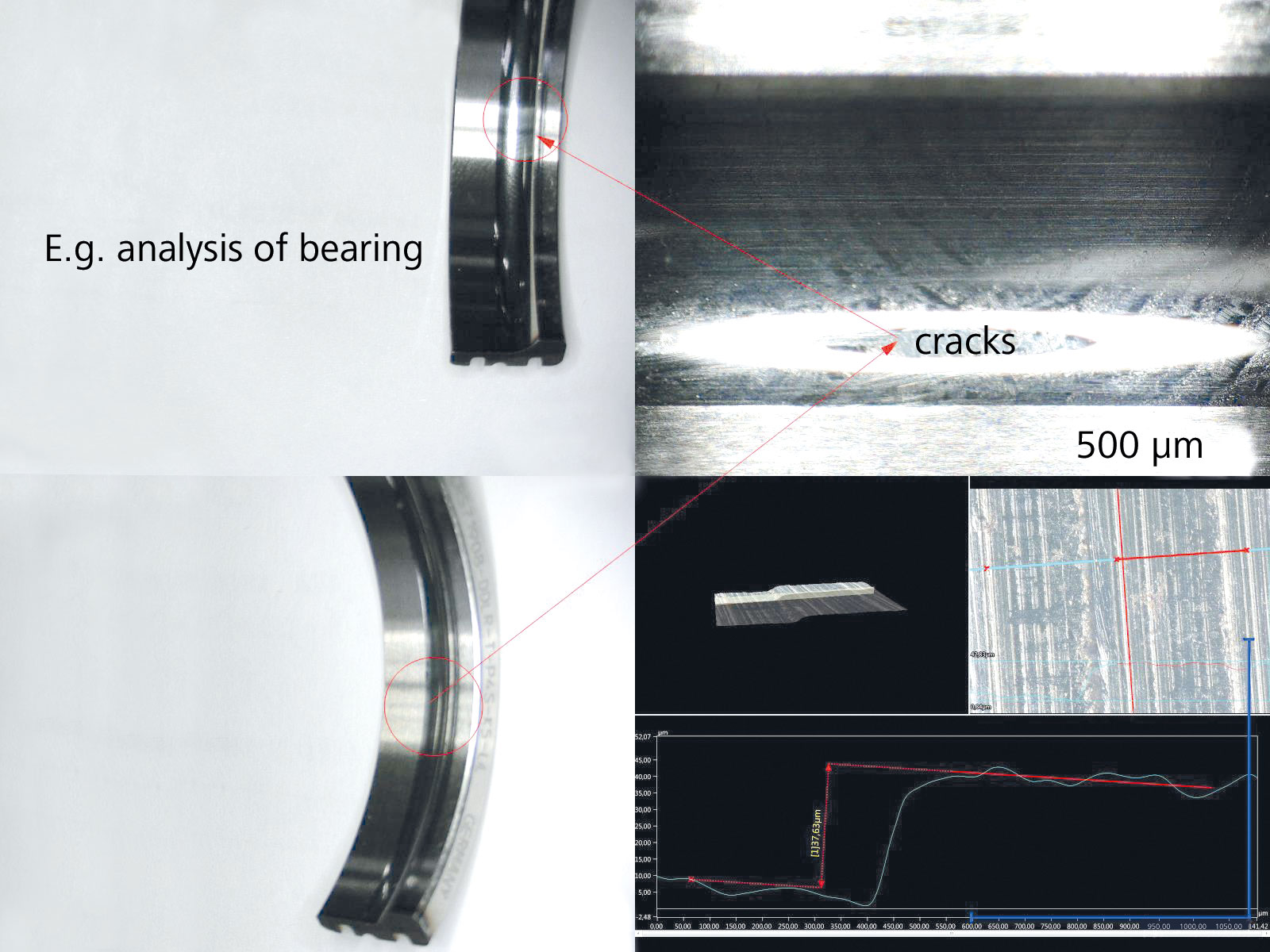

Only those who take a closer look know the ins and outs of their products.

KESSLER has the very latest state-of-the-art measurement technology for testing its components under operational conditions. The application analysis in realistic processes enables us to provide optimum service at the customer site and in our "Technology Center".